A case study of changes in land use during exploration and production

Introduction

The Pinedale field is the sixth-largest gas field in the United States.1 The core development area covers about 70 square miles in a sparsely populated area of southwest Wyoming, 70-100 miles north of Rock Springs.2 In 2015, the Pinedale field produced 4 million barrels of gas condensate and 436 billion cubic feet of natural gas,3 making it the largest natural gas-producing field in Wyoming (for comparison, the vast Marcellus Shale in the Appalachian basin produced 6 trillion cubic feet of natural gas in 20154). Through 2012, the field had produced 3.9 trillion cubic feet of natural gas – only 10% of its potentially recoverable gas reserves – so operations may continue for many years.5

Field operations impact nearby small towns and large populations of sage grouse (under special protections6), pygmy rabbits (endangered in some of their range7), and pronghorn.1 The field is also an important winter range for thousands of mule deer.8 Since the field started production in the late 1990s, improvements in drilling, land use, air emissions, and water handling practices have reduced the physical, societal, and environmental impacts of drilling and production in the Pinedale field.

Although Pinedale provides a good example of improvements in low-impact gas production, continued improvements will be important to the long-term preservation of this region throughout the field’s production, eventual closure, and restoration to its pre-drilling state.

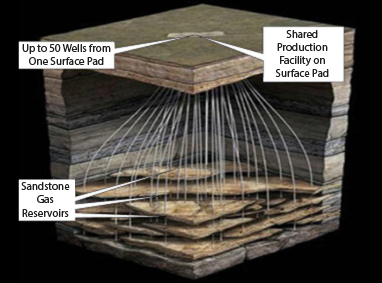

Schematic showing how curved wells allow a large area of gas-producing rock to be accessed from a single well site. Image credit: AAPG Wiki.5

Directional Drilling from Multi-Well Pads

The gas-producing zone of rocks in the Pinedale field is almost 6,000 feet thick and made of many lens-shaped layers of sandstone. Over 2,500 curved wells have been drilled to tap into the producing zone, 8,500-14,000 feet underground, at distances thousands of feet horizontally from the drilling site. These wells are hydraulically fractured to allow gas to flow out of the otherwise impermeable sandstone.

Federal Management Plan

Over 80% of the field area is federal land overseen by the U.S. Bureau of Land Management (BLM), which must approve an operator’s plan of operations and reclamation before drilling. Commercial development of the field was enabled by the use of hydraulic fracturing techniques that were applied starting in the 1990s. Early operations were governed by a 1988 Resource Management Plan/Environmental Impact Statement9,10 developed by BLM with input from the public and other government agencies. The Resource Management Plan/Environmental Impact Statement was updated in 200811 to require or promote environmentally beneficial changes while allowing additional drilling.

Aerial photos of a well site in the Pinedale Field. Left: Well site during drilling in 2009. Right: Same site in 2015 – the site contains 17 wells, its area has been reduced from 15.3 to 6.04 acres, and the reclaimed 9.26 acres are being revegetated. Image credit: Courtesy of Timothy Zebulske, BLM Pinedale Field Office.

Innovations that Reduce the Land Use and Environmental Impact of Operations12

- The 2008 Resource Management Plan (RMP) allows for the construction of multi-well sites concentrated in designated development areas, located away from streams and nesting, calving, and winter grazing areas. This allows drilling and other operations throughout the year in the designated development areas while reducing habitat fragmentation and leaving 92% of the Pinedale area undisturbed. Well sites used in early field development required about 4 acres per well and usually contained one or two wells. New multi-well sites approved in the RMP are permitted to have up to 60 wells per site. As of 2012, long-term disturbance per well was 0.44 acres and total disturbance per well was 1.26 acres, with incremental improvements in these numbers each year.5

- A few new wells have also been drilled horizontally, and a small number of horizontal wells may be drilled in the future. Horizontal wells can tap a larger area of gas-rich rocks, so fewer wells are required to extract the gas.

- Recycling of produced water began in 2006. Idle gas-gathering pipelines were repurposed to move produced water to central processing facilities and move processed water to new hydraulic fracturing sites. This system removed the need for hundreds of thousands of truck trips and reduced air pollution and wildlife disruption.13 Several years later, water processing facilities were updated to clean some of the produced water to drinking water standards. This water is used for cement and other field operations that demand fresh water. Large amounts of treated water are also released into the local river – over one million gallons in the first year of operation.14 Such water treatment and re-use practices are particularly important in semi-arid southwest Wyoming.

- More efficient drilling techniques have reduced drilling times from 45-50 days per well to 10-11 days per well, which reduces some environmental impacts such as air pollutant emissions from engines and truck traffic.

- The shift to year-round operations in designated development areas encourages a stable, less transient workforce, which benefits nearby communities.

- The Pinedale field is part of the Upper Green River Basin Ozone Nonattainment Designation Area designated by the U.S. Environmental Protection Agency (EPA) in 2012. In response to this designation, Wyoming expanded its efforts to reduce ozone levels in the area. State regulations included emission controls on storage tanks, pneumatic controllers, and drilling rig engines, as well as “green” well completions that capture the gases and fluids produced as a well is cleaned of fluids and debris after hydraulic fracturing.15 These requirements helped reduce ozone levels in the Pinedale area, and in 2016 the EPA determined that the Green River Basin area had met the required ozone standards.16

- BLM rules require ongoing site reclamation. When active drilling operations end, well sites need less space and smaller access roads. Operators are required to promptly restore and revegetate unused areas under BLM oversight.

More Resources

Wyoming State Geological Survey – Cultural Geology Guide: Pinedale Anticline.

U.S. Bureau of Land Management (2008). Pinedale Resource Management Plan.

U.S. Department of Energy, Office of Oil and Natural Gas – Footprint Reduction.

References

1 Wyoming State Geological Survey – Cultural Geology Guide: Pinedale Anticline.

2 U.S. Bureau of Land Management (2008). Record of Decision for the Supplemental Environmental Impact Statement for the Pinedale Anticline Oil and Gas Exploration and Development Project, Sublette County, Wyoming.

3 “Wyoming natural gas production falls for sixth consecutive year; U.S. production rises.” B. Storrow, Casper Star Tribune, January 5, 2016.

4 U.S. Energy Information Administration (2017). Marcellus Region: Drilling Productivity Report, July 2017.

5 AAPG Wiki – Pinedale field.

6 U.S. Fish and Wildlife Service – Greater Sage-Grouse.

7 Hayden-Wing Associates, LLC (2016). Pygmy Rabbit Monitoring in the Pinedale Anticline Project Area, Sublette County, Wyoming, 2016. Report prepared for Wyoming Game and Fish Department, Pinedale Anticline Project Office, and Bureau of Land Management, Pinedale, Wyoming.

8 Sawyer, H. et al. (2017). Mule deer and energy development – Long-term trends of habituation and abundance. Glob. Chang. Biol., 23, 4521-4529.

9 U.S. Bureau of Land Management (1987). Pinedale Resource Area: proposed resource management plan / environmental impact statement: final.

10 U.S. Bureau of Land Management (1989). Record of decision and resource management plan for the Pinedale Resource Area.

11 U.S. Bureau of Land Management (2008). Pinedale Resource Management Plan.

12 Except where otherwise referenced, information in this section comes from communications with BLM Pinedale Anticline Project Office staff, June 30, 2017.

13 Boschee, P. (2012). Handling Produced Water from Hydraulic Fracturing. Oil and Gas Facilities Magazine, 1 (1).

14 Shafer, L. (2011). Water Recycling and Purification in the Pinedale Anticline Field: Results from the Anticline Disposal Project. SPE Americas E&P Health, Safety, Security, and Environmental Conference, 21-13 March, Houston, Texas, USA.

15 Wyoming Department of Environmental Quality (2015). Proposed Revisions to the Chapter 6, Section 2 Oil and Gas Production Facilities Permitting Guidance. Technical Support Document.

16 U.S. Environmental Protection Agency (2016). Determinations of Attainment by the Attainment Date, Extensions of the Attainment Date, and Reclassification of Several Areas for the 2008 Ozone National Ambient Air Quality Standards. Federal Register, 81 (86), p. 26697-26722, May 4, 2016.

Petroleum and the Environment

Download a full PDF of Petroleum and the Environment (free) or purchase a printed version ($19.99).

Other parts in this series:

1. Petroleum and the Environment: an Introduction

2. Water in the Oil and Gas Industry

3. Induced Seismicity from Oil and Gas Operations

4. Water Sources for Hydraulic Fracturing

5. Using Produced Water

6. Groundwater Protection in Oil and Gas Production

7. Abandoned Wells

8. What Determines the Location of a Well?

9. Land Use in the Oil and Gas Industry

10. The Pinedale Gas Field, Wyoming

11. Heavy Oil

12. Oil and Gas in the U.S. Arctic

13. Offshore Oil and Gas

14. Spills in Oil and Natural Gas Fields

15. Transportation of Oil, Gas, and Refined Products

16. Oil Refining and Gas Processing

17. Non-Fuel Products of Oil and Gas

18. Air Quality Impacts of Oil and Gas

19. Methane Emissions in the Oil and Gas Industry

20. Mitigating and Regulating Methane Emissions

21. Regulation of Oil and Gas Operations

22. Health and Safety in Oil and Gas Extraction

23. Subsurface Data in the Oil and Gas Industry

24. Geoscientists in Petroleum and the Environment

Glossary of Terms

References