Many existing products provide a low-cost, low-energy source of materials

Why Recycle?

Recycling saves energy, money, materials, and natural resources, while reducing landfill use. It supplements the national supply of essential materials, reducing dependence on imports. As more minerals and materials become critically important - particularly in advanced technologies - the role of recycling as a source of these materials is likely to increase.

85% of all used automobiles are recycled, providing large quantities of metals and other materials. Image Credit: Adam DuBrowa/FEMA

Old Scrap and New Scrap

There are two main sources of material for recycling: old scrap (from post-consumer products like cars, electronics, and cans) and new scrap (from the manufacturing process, such as excess material from shaping, cutting, and molding products). Old and new scrap provide different proportions of the recycled material for different metals. Almost all recycled lead comes from old scrap; most recycled copper is from new scrap; and new and old scrap contribute roughly equally to recycled aluminum. Overall, recycling provides 40-50% of the U.S. metal supply.1,2

Saving Energy

Some mineral resources require huge amounts of energy to refine from primary ore. Recycling existing material requires much less energy. In the U.S., recycling saves enough energy to power tens of millions of homes.

High recycling rates but low supply

For some materials, recycling efficiency is already near its limit. Over 90%2 of the gold, lead, silver, titanium, and vanadium in recyclable products is currently recycled, but this only provides 30-70% of the necessary supply of these metals.2 This is largely due to dissipative uses that make recycling products for these metals physically impossible (see “Limitations”, below) or economically unfavorable.

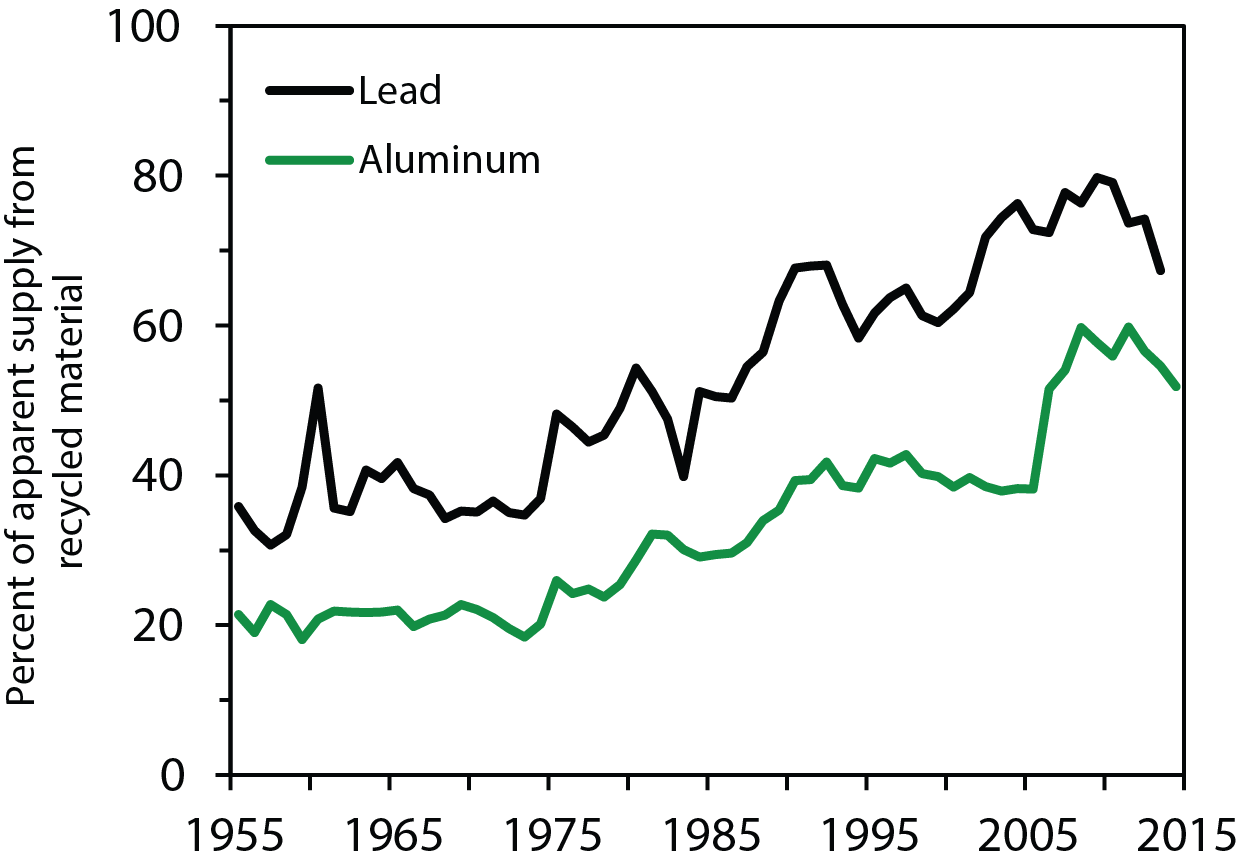

The proportion of national demand met by recycling has significantly increased for many metals. Recycling now provides the majority of the lead and aluminum supply in the U.S. Data Source: U.S. Geological Survey.

Limitations

Although recycling is constantly improving and expanding, there are a number of issues limiting its efficacy:

- Lag times: A product can only be recycled once it is no longer in use. The “lag time” between the manufacture of a product and its availability for recycling varies between products. For aluminum cans it averages 65 days; for cars it is 12-15 years; for building materials it can be 50 years or more.4

- Dissipation: Many mineral resources are used in dispersive applications or in materials that can’t be easily recovered for recycling. These include titanium dioxide in paint, phosphorus in fertilizer, and road salt.

- Cost and quality: Some minerals are much cheaper and easier to obtain from their primary sources than from recycling. With the exception of glass,3 asphalt, and aggregates,6 recycling is limited for non-metals, especially stones, clays, salts, and silicate minerals.

Steel Recycling: more than just iron

In 2014, iron and steel accounted for 91% of all metal recycled in the United States.1 Many mineral resources are mined mainly for use in steel alloys. These include chromium, manganese, molybdenum, nickel, niobium, and vanadium. Steel recycling currently reduces the need for primary production of these elements by 20-40%.3

Rare Earth Elements

There is currently very little recycling of rare earth elements (REE).7 Many products containing REE are recycled for other components (catalytic converters are recycled for platinum and palladium; colored glass containing REE is recycled for other glass uses). Methods for REE recycling are being developed, and recycling may be a much more important source of REE in the future, particularly in the event of shortages or supply restrictions. Possible sources of scrap containing REE include electronics, lasers, phosphor-based lamps, rare-earth magnets, ceramics, and batteries.

Just the numbers (2010)1

Quantities of recycled metals (million metric tons per year)1

Total metals recycled: 64.7

Exports: 18.1

Imports: 5.1

Value of recycled metal for the most common industrial metals1

$39.5 billion

Recycling rates for highly recycled metals (% of apparent supply)1

Lead: 70-80%

Aluminum, iron & steel: 50-60%

Recycling rates for common items3

Automobiles: 85%

Iron & steel appliances: 89%

Steel cans: 70%

Construction materials

Plates & beams: 98%

Rebar & other materials: 71%

Glass containers: 34%

Energy savings for production by recycling vs. primary sources

Aluminum: 92%4

Beryllium: 80%3

Lead: 75%2

Iron & steel: 72%2

Apparent supply is an estimate of the amount of material available to industry, including mine production, recycled material, international trade, and changes in stocks/inventories.

More Resources

References

1 2014 Minerals Yearbook, U.S. Geological Survey

2 Overview of Flow Studies for Recycling Metal Commodities in the United States, U.S. Geological Survey

3 2017 Mineral Commodity Summaries, U.S. Geological Survey

4 U.S. Energy Requirements for Aluminum Production, U.S. Department of Energy

5 Historical Statistics for Mineral and Material Commodities in the United States, U.S. Geological Survey

6 Recycled Aggregates - Profitable Resource Conservation, U.S. Geological Survey

7 Rare Earth Elements - End Use and Recyclability, U.S. Geological Survey

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

You are free to share or distribute this material for non-commercial purposes as long as it retains this licensing information, and attribution is given to the American Geosciences Institute.